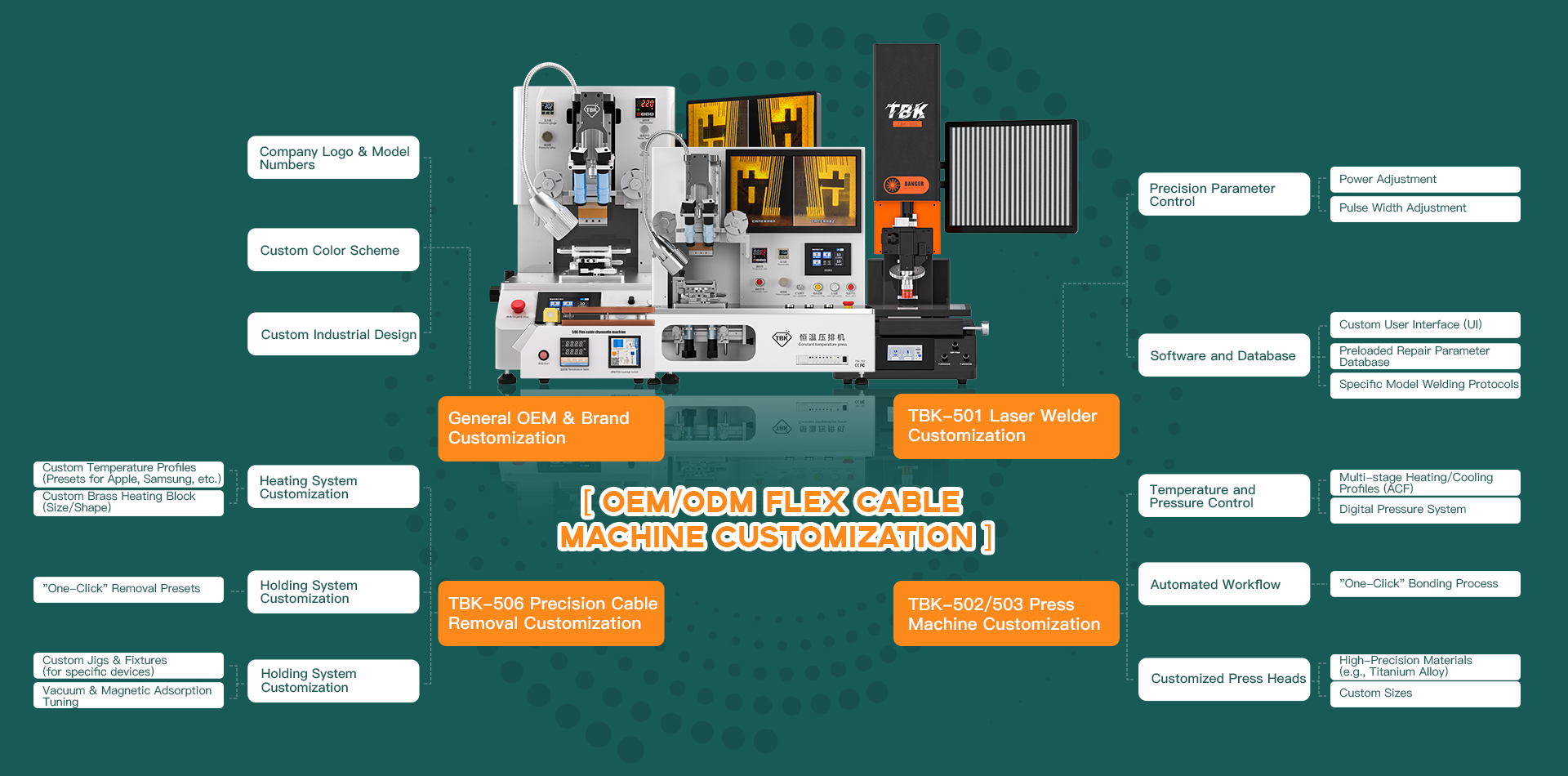

OEM/ODM Flex Cable Machine Customization

We offer comprehensive OEM/ODM services that allow for the in-depth customization of our flex cable repair equipment. We tailor the core functions of each machine to your specific business needs—whether you focus on particular brands, device types, or unique repair scenarios—ensuring the final solution meets your exact process requirements.

3-Step Screen Flex Cable Repair Process

Step 1: Remove Cable (TBK-506) First, use the TBK-506 to safely heat and remove the damaged flex cable from the screen.

Step 2: Repair Circuit (TBK-501) Next, use the TBK-501 laser machine to repair the screen's internal fine circuits (e.g., fixing bright lines, broken traces).

Step 3: Bond Cable (TBK-503/502) Finally, use the TBK-503 (or 502) bonding machine to precisely press the new flex cable back onto the screen, restoring display and touch functions.

Flex Cable Machines Functions

For common touch failures and display problems on smartphone screens, we provide advanced repair equipment solutions to help you quickly and efficiently restore the normal functions of your phone screen.

TBK501:Touch troubleshooting solution

For screen display problems, such as screen blur, flickering or color line problems (including white lines, green lines, purplelines, pink lines, etc.), the TBK-501 laser machine can provide a first-class solution together with the press and discharge machine.

TBK502/503: Show problem solution

When there is touch failure on the mobile phone screen, such as touch disconnection, cable breakage, cable corrosion due to water ingress, or IC breakage, TBK-502 and TBK-503 are ideal choices for repair processing.

Get A Quick Quote

TBK provides the most cost-effective machines. Fill out the form below, and we will get back to you promptly. Thank you for choosing TBK.