OEM/ODM Motherboard Repair Workstation Customization

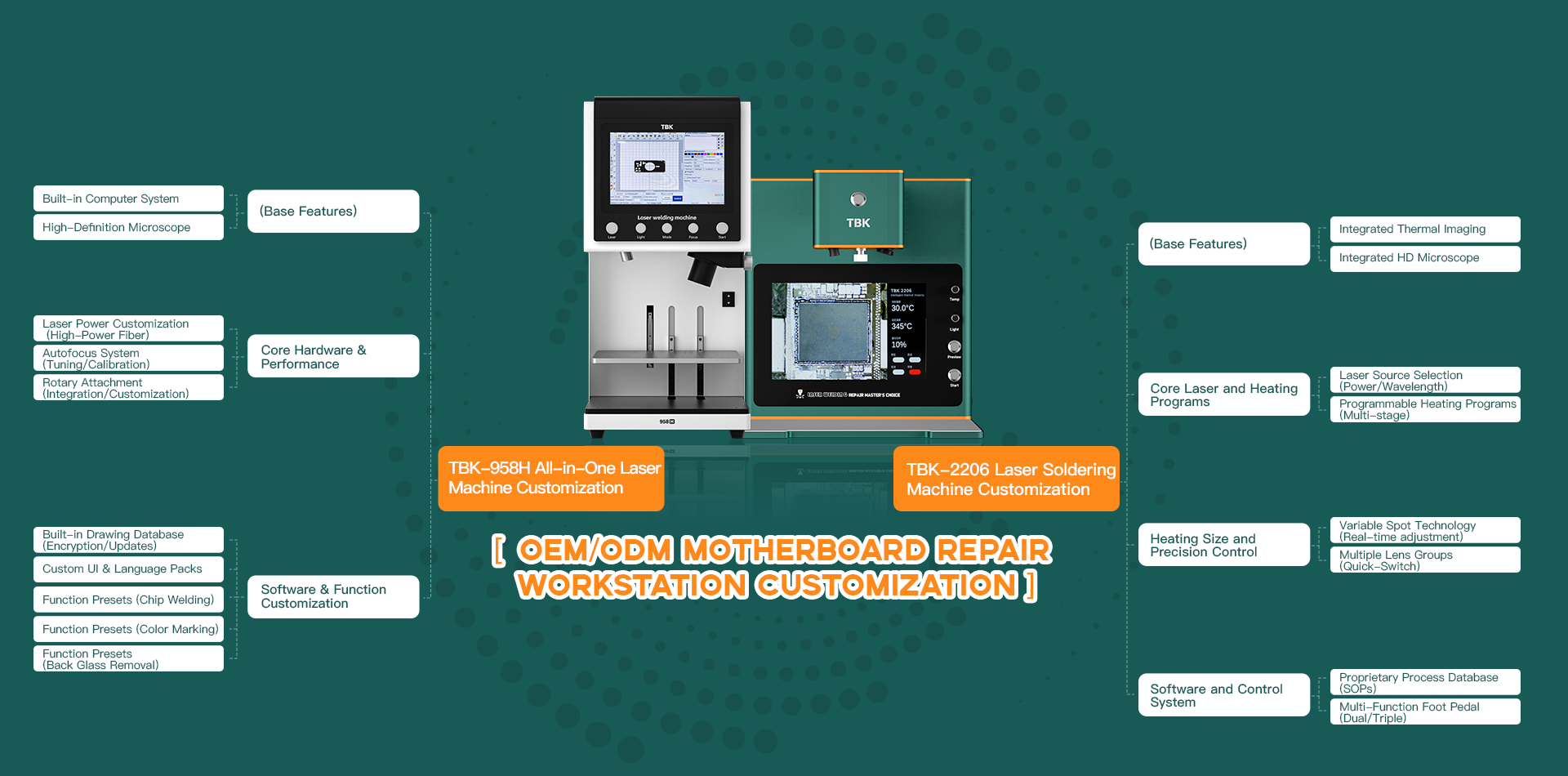

As the new core of the precision repair and multi-application process, the TBK-2206 and TBK-958H series offer extensive and in-depth customization options, designed to meet the ultimate demands for efficiency, accuracy, and versatility from top-tier technicians.

TBK Laser Motherboard Repair & Electrical Diagnosis Workflow

Whether you are performing detailed electronic repairs, such as welding battery nickel sheets or removing phone back covers using its extensive library of built-in drawings, or creating custom designs, this machine handles it all. It can produce vibrant color markings on stainless steel and is adaptable for engraving a variety of materials. For cylindrical items, an optional rotary attachment expands its capabilities even further. It is a complete solution for small businesses, repair shops, and hobbyists who require professional-grade laser capabilities.

One-Stop Mobile Motherboard Repair Machine & Accessories Solution

We provide a one-stop solution for mobile motherboard repair, designed to simplify the workflow and increase efficiency. This solution includes not only the two core machines for power-on testing (DC Power Supply) and precision soldering (Laser Soldering Machine), but also covers the full range of accessories and consumables needed throughout the process, helping technicians easily tackle any motherboard repair challenge.

The entire repair process follows two core steps:

Power-on Diagnosis: Use the DC Power Supply to power the motherboard. By analyzing data such as current waveforms, you can quickly diagnose functional issues like short circuits or open circuits.

Precision Repair: After confirming the fault, operate the Laser Soldering Machine to perform precise, non-destructive desoldering and soldering, using the full set of accessories and consumables to complete the final repair.

Complete Accessory Support

Function: To supply all necessary auxiliary tools and consumables required for the entire repair process.

In addition to the three core machines, we also provide all the accessories needed throughout the process. This ensures that repair work can proceed smoothly without the hassle of sourcing miscellaneous items.

Soldering Consumables: Includes various types of solder paste, flux, and solder wire.

Operating Tools: We offer anti-static tweezers, spudgers, screwdriver sets, and cleaning brushes.

Auxiliary Accessories: Such as BGA reballing stencils, high-temperature tape, test cables, and spare nozzles for the machines.

Cleaning Supplies: Includes circuit board cleaner and lint-free cloths.

We ensure you have the right tools and materials available for every step of the repair.

Auxiliary Systems, Accessories & Branding

Get A Quick Quote

TBK provides the most cost-effective machines. Fill out the form below, and we will get back to you promptly. Thank you for choosing TBK.